Tiger clamps are a general term for a class of clamping tools named for their strong clamping force and secure grip. They specifically refer to different tools in different application fields. This is a powerful mechanical clamp based on the screw or lever principle, mainly used for fixing workpieces in industrial manufacturing, woodworking, or maintenance.

Working principle and characteristics: It generates a huge clamping force through the transmission mechanism, and its stability is vividly compared to "a tiger's bite".

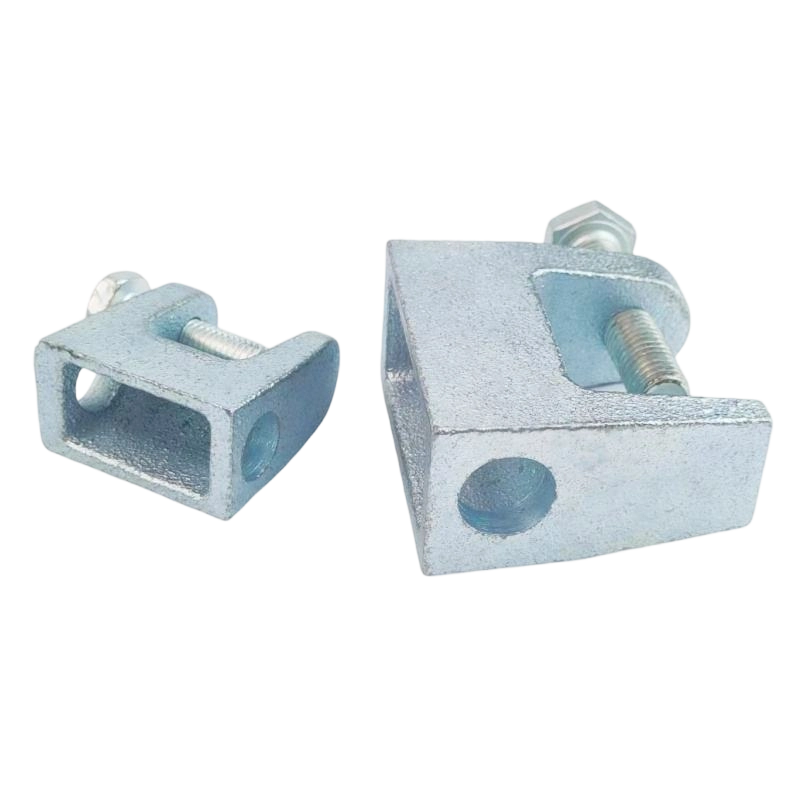

Main materials and characteristics:

Stainless steel: resistant to corrosion and wear, suitable for environments demanding aesthetics and durability.

Carbon steel: High strength, but prone to rusting, suitable for scenarios requiring strong support.

Galvanized carbon steel: It possesses rust-proofing capabilities and is suitable for use in damp environments.

Aluminum alloy: Lightweight, with good thermal and electrical conductivity, but poor low-temperature strength, suitable for high-load environments.

Key parameters and styles:

Opening size: Common sizes include 18mm, 20mm, 25mm, 35mm, 45mm, etc. The longer the opening, the wider the clamping range.

Clamping range: Multiple ranges are available, such as 0-25mm, 10-39mm, etc.

Styles: Mainly including outer hexagonal style (suitable for operations requiring high torque), butterfly-shaped hand-tight style (suitable for quick and frequent adjustments), and lifting ring style (good stability during lifting).