The Versatile Backbone for Modern Structures.

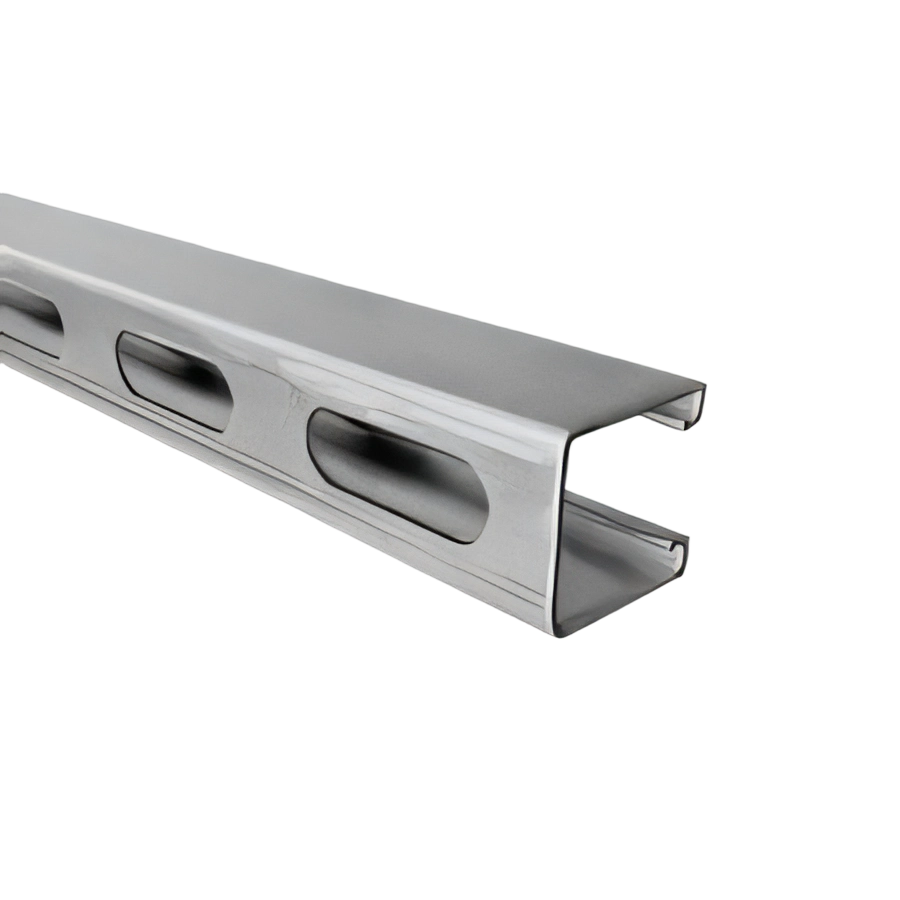

Our Precision-Formed C-Channel Steel, commonly known as C-Purlins, is the essential component for building robust, reliable, and cost-effective frameworks. Cold-formed from high-quality [Specify Steel Grade, e.g., G450 Galvanized Steel], it offers an exceptional strength-to-weight ratio, making it the preferred choice for structural support in commercial buildings, industrial warehouses, residential construction, mezzanine floors, and heavy-duty equipment frames.

C-shaped steel, a steel material with a "C" shaped cross-section, is widely used in construction, bridges, engineering machinery, and other fields due to its excellent mechanical properties and durability. It is made from hot-rolled or cold-rolled strip steel as the base material and is automatically processed and formed by a C-shaped steel forming machine. The processing flow includes 9 steps, such as feeding, straightening, and forming.

The distinctive “C” shape provides excellent load-bearing capacity and directional rigidity while remaining lightweight and easy to handle. Each length features clean, square-cut ends and consistent dimensional accuracy for fast, straightforward installation and seamless integration with other structural members. Available in both standard and custom sizes, our C-channel can be easily drilled, welded, or bolted, offering unparalleled design flexibility.

Specification and type

C-shaped steel is divided into five specifications based on its height: 80, 100, 120, 140, and 160, with a length typically not exceeding 12 meters. Common specifications include C80×40×20×2.5, C100×50×20×2.5, etc. There are over twenty types of C-shaped steel, including galvanized C-shaped steel, hot-dip galvanized cable tray C-shaped steel, and glass slot C-shaped steel.

Application field

C-shaped steel is primarily utilized as purlins and wall beams in steel structure buildings, and can be assembled into lightweight roof trusses, brackets, and other architectural components. Additionally, it is also used in structural components such as columns, beams, and arms in mechanical and light industrial manufacturing.

advantage

Galvanized C-shaped steel boasts advantages such as durability, comprehensive protection, strong coating toughness, excellent reliability, time and labor saving, and low cost. Compared to traditional hot-rolled steel sections, cold-formed C-shaped steel has a 50%-60% increase in turning radius and a 0.5-3 times increase in sectional moment of inertia, resulting in a 30%-50% saving in steel material.

| Product code | Nominal diameter | W(mm) | H(mm) |

| LS74 0900 | DN80-DN40 | 127 | 155 |

| LS75 0900 | DN80-DN50 | 127 | 155 |

| L584 0900 | DN100-DN40 | 147 | 178 |

| LS85 0900 | DN100-DN50 | 147 | 178 |

| LS94 0900 | DN125-DN40 | 175 | 204 |

| LS95 0900 | DN125-DN50 | 175 | 204 |

| LSC4 0900 | DN148-DN40 | 204 | 225 |

| LSC5 0900 | DN148-DN50 | 204 | 225 |

| LSC6 0900 | DN148-DN65 | 204 | 239 |

| LSB4 0900 | DN200-DN40 | 270 | 282 |

| LSB5 0900 | DN200-DN50 | 270 | 282 |

| LSB6 0900 | DN200-DN65 | 270 | 296 |

| LSB7 0900 | DN200-DN80 | 270 | 296 |