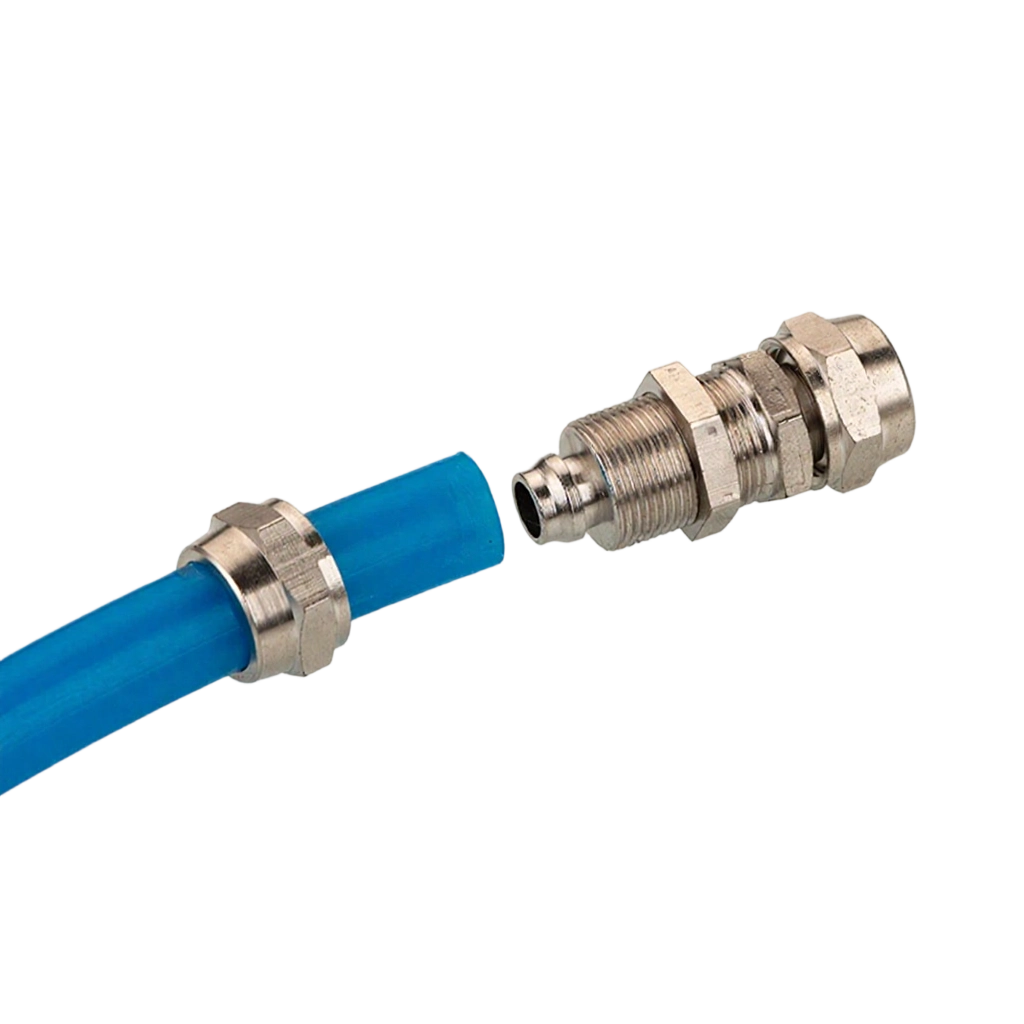

The SealTite™ Hose Connector is engineered to deliver a fast, secure, and perfectly sealed link between your hose and equipment. Crafted from high-grade, corrosion-resistant, this heavy-duty fitting features a precision-machined swivel nut that allows for easy hand-tightening without twisting the hose, preventing kinks and wear.

Material and Type: Common materials include stainless steel (such as 304 and 316, which are corrosion-resistant and suitable for sanitary or chemical environments) and carbon steel (high strength, low cost, commonly used in industrial hydraulic systems). The main body of the hose may be a metal bellows or a rubber composite tube. Types can be divided into crimped hose connectors (which are integrally formed with the hose through hydraulic crimping, suitable for high-pressure hoses) and ferrule-type connectors (which use ferrules to cut into the hose for sealing, facilitating easy disassembly and assembly). In addition, there are variants such as internal and external thread nut sets, which adapt to different interface specifications through the combination of internal and external threads.

Structure and working principle: The hose connector with nut is usually composed of a connector body, a nut, and a hose assembly (such as a corrugated hose or rubber hose). The connector body and the hose are connected by crimping, welding, or ferruling, while the nut is screwed onto the connector body through threads. During operation, the tightening force of the nut drives the sealing structure (such as conical surface fit, composite gasket, or O-ring) to deform, forming an end face seal or metal hard seal, thereby preventing fluid or gas leakage. Some designs adopt a double ferrule structure, which enhances vibration resistance and sealing reliability through the engagement of front and rear ferrules.

The heart of the connector is its integrated made from, which compresses evenly against a flat seat to ensure a drip-free seal under pressure. This design is ideal for a wide range of applications—from high-pressure water and air tools in workshops and gardens to industrial fluid transfer and agricultural irrigation systems. Its robust construction withstands pressures up to and repeated use, providing lasting reliability.

Connection method and sealing mechanism: The connection relies on thread standards (such as NPT, PT, or G threads). When the nut is tightened, it pushes the sealing element into contact with the joint end surface, forming a conical or flat seal. In high-pressure environments, fine thread threads are often used in combination with composite washers to enhance sealing performance. For metal hose connectors, traditional rubber washers may be replaced by a hard seal between the conical ring at the end of the corrugated tube and the metal ring, thereby enhancing durability.

| Product code | Nominal diameter | W(mm) | H(mm) |

| LS74 0900 | DN80-DN40 | 127 | 155 |

| LS75 0900 | DN80-DN50 | 127 | 155 |

| L584 0900 | DN100-DN40 | 147 | 178 |

| LS85 0900 | DN100-DN50 | 147 | 178 |

| LS94 0900 | DN125-DN40 | 175 | 204 |

| LS95 0900 | DN125-DN50 | 175 | 204 |

| LSC4 0900 | DN148-DN40 | 204 | 225 |

| LSC5 0900 | DN148-DN50 | 204 | 225 |

| LSC6 0900 | DN148-DN65 | 204 | 239 |

| LSB4 0900 | DN200-DN40 | 270 | 282 |

| LSB5 0900 | DN200-DN50 | 270 | 282 |

| LSB6 0900 | DN200-DN65 | 270 | 296 |

| LSB7 0900 | DN200-DN80 | 270 | 296 |