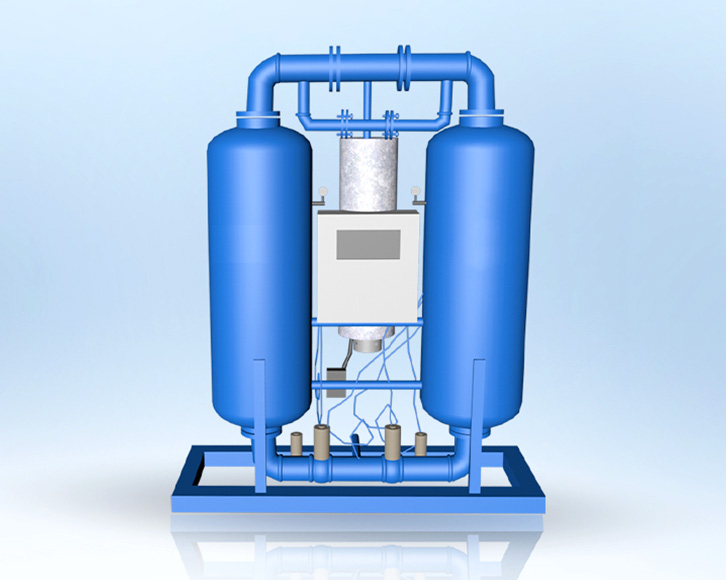

Adsorption Dryer

Air Handling Capacity: 1.5 ~ 200 Nm³/min

Operating Pressure: 0.4~1.0 MPa

Pressure Loss: ≤0.03 MPa

Pressure Dew Point: -70℃

Weight: See catalog

Dimensions: Consult customer service

Brand: Desu

Advantages

Strong adsorption, strong wear resistance, long service life, and improved performance.

Durable, highly compressible, stable performance, powerful.

The principle of an adsorption dryer:

Utilizing pressure swing adsorption (PSA) regeneration cycle, air is passed through two drying cylinders, A and B, filled with adsorbent. One cylinder operates under high partial pressure (working pressure) water vapor, while the other operates under low partial pressure (atmospheric pressure). A pre-programmed time sequence then switches between the two cylinders.

Performance improvement

Low operating noise: Utilizing a silent one-way valve and a high-performance silencer, noise levels are minimized during operation and exhaust.

Automatic low-pressure protection: When the working pressure falls below the valve's normal control pressure, the system automatically shuts down and restarts upon pressure recovery, preventing abnormal system pressure caused by valve malfunction.

Automatic pressurization function: The system automatically pressurizes before valve switching, ensuring pressure equalization within the cylinder and maintaining pressure stability. This prevents pressure fluctuations in the pipeline from impacting adsorption and extends the adsorbent's lifespan.

Pneumatic valve

Reliable performance and sensitive operation can prevent malfunctions such as air leakage or valve jamming caused by poor valve performance.

Solenoid valve

Employing German (NASS) coil commutation solenoid valves, ensuring rapid, reliable, and long-lasting switching.

Pneumatic actuator

Employs a high-torque aluminum alloy pneumatic actuator; high torque, smooth operation, and internal self-lubrication; no lubricant required.

Smart control screen

It adopts a PLC and LCD screen controller with a Chinese interface, which is easy to understand and convenient to operate and maintain.

| Heatless regeneration adsorption dryer (DN15~2000WR) | |||||||||

| model | air handling capacity | Air inlet diameter | weight | size | |||||

| Standard model | Standard model | Standard model | |||||||

| Nm³min | G thread/DN flange | (kg) | L/W/H | ||||||

| DN15WR | 1.5 | ZG1" | 125 | 750/350/1440 | |||||

| DN26WR | 2.6 | 189 | 750/350/1640 | ||||||

| DN40WR | 3.8 | ZG1.5” | 285 | 1000/500/1518 | |||||

| DN65WR | 6.5 | 420 | 1000/450/1950 | ||||||

| DN85WR | 8.5 | ZG2.0 | 550 | 1100/500/1910 | |||||

| DN110WR | 11 | 650 | 1150/500/2050 | ||||||

| DN138WR | 13.8 | 750 | 1200/550/2100 | ||||||

| DN150WR | 16 | DN65 | 860 | 1250/575/2160 | |||||

| DN200WR | 23 | DN80 | 965 | 1400/550/2220 | |||||

| DN250WR | 27 | DN80 | 1250 | 1450/550/2480 | |||||

| DN300WR | 33 | DN80 | 1575 | 1500/600/2550 | |||||

| DN400WR | 45 | DN100 | 1758 | 1900/1000/2710 | |||||

| DN500WR | 55 | DN125 | 2300 | 2000/1200/2766 | |||||

| DN600WR | 65 | DN125 | 2500 | 2100/1280/2780 | |||||

| DN800WR | 85 | DN125 | 2800 | 2400/1350/2820 | |||||

| DN1000WR | 100 | DN150 | 3650 | 2650/1500/2930 | |||||

| DN1500WR | 150 | DN200 | 5200 | 2800/1800/3000 | |||||

| DN2000WR | 200 | DN250 | 7250 | 2900/2000/3200 | |||||

| Micro-heat regenerative adsorption dryer (DN15~2000VR) | |||||||||

| model | air handling capacity | Air inlet diameter | Heater power | weight | size | ||||

| Standard model | Standard model | Standard model | |||||||

| Nm³/min | G thread/DN flange | kw | (kg) | L/W/H | |||||

| DN15VR | 1.5 | ZG1” | 1.2 | 125 | 750/350/1440 | ||||

| DN26VR | 2.6 | 1.5 | 189 | 750/350/1640 | |||||

| DN40VR | 3.8 | ZG1.5” | 2.1 | 285 | 1000/500/1518 | ||||

| DN65VR | 6.5 | 3 | 420 | 1000/450/1950 | |||||

| DN85VR | 8.5 | ZG2.0 | 4 | 550 | 1100/500/1910 | ||||

| DN110VR | 11 | 4.5 | 650 | 1150/500/2050 | |||||

| DN130VR | 13.8 | 5 | 750 | 1200/550/2100 | |||||

| DN150VR | 16 | DN65 | 5.5 | 860 | 1250/575/2160 | ||||

| DN200VR | 23 | DN80 | 6 | 965 | 1400/550/2220 | ||||

| DN250VR | 27 | DN80 | 8 | 1250 | 1450/550/2480 | ||||

| DN300VR | 33 | DN80 | 10 | 1575 | 1500/600/2550 | ||||

| DN400VR | 45 | DN100 | 12 | 1758 | 1900/1000/2710 | ||||

| DN500VR | 55 | DN125 | 15 | 2300 | 2000/1200/2766 | ||||

| DN600VR | 65 | DN125 | 18 | 2500 | 2100/1280/2780 | ||||

| DN800VR | 85 | DN125 | 24 | 2800 | 2400/1350/2820 | ||||

| DN1000VR | 100 | DN150 | 30 | 3650 | 2650/1500/2930 | ||||

| DN1500VR | 150 | DN200 | 45 | 5200 | 2800/1800/3000 | ||||

| DN2000VR | 200 | DN250 | 60 | 7250 | 2900/2000/3200 | ||||

| *Our company is committed to continuous product improvement and reserves the right to make design changes. Configuration or parameter changes will not be notified separately. | |||||||||