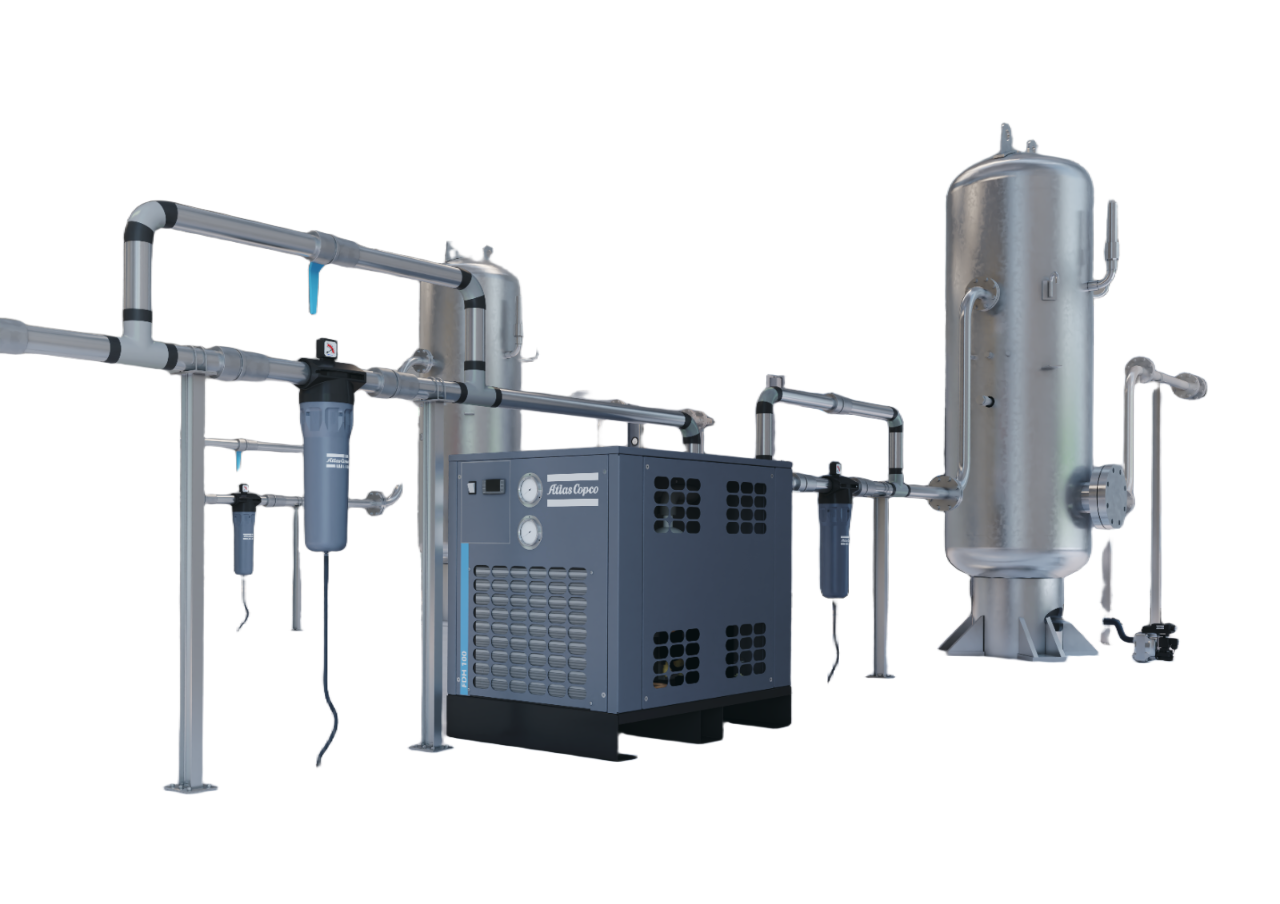

The main advantages of the FDH high-pressure air refrigeration dryer:

High-efficiency dehumidification

Prevent the accumulation of condensate water in the compressed air system to prevent rusting and damage to the equipment.

Energy-saving operation

Low power consumption ensures the machine operates economically and effectively without adversely affecting the drying performance.

Compact modular design

The space-saving structure is easy to install, even in compact industrial Spaces.

Reliable dew point control

Maintain a stable dew point to protect sensitive applications from moisture-related issues.

Environmentally friendly refrigerant

Use environmentally friendly refrigerants to meet cooling demands while promoting sustainable development.

Specification

Air flow rate: 270 to 1,620 m³/h (depending on model specification)

Pressure dew point: +3°C to +7°C

Pressure range: Up to 43 bar

Cooling method: Air-cooled

Refrigerant: R-410A, environmentally friendly

Input power: 5 to 19 kW, depending on the model

Application

The Atlas Copco FDH high-pressure air-cooled dryer is specifically designed for industries where critical processes rely on clean and dry compressed air. Its main applications include:

Food & Beverages: Ensure that the compressed air used in packaging, bottling or food preparation remains dry and free from contaminants.

PET application: Ensure that the air entering the blow molding machine is dry to prevent PET blow bottles from getting damp.

Manufacturing: Ensure the smooth operation of pneumatic tools and machinery.

Automobiles: By preventing equipment from getting damp and damaged, maintain the efficient operation of the production line.

Textile: Prevent moisture from affecting the production of fabrics and fibers.

Pharmaceuticals: Protect sensitive production environments from excessive moisture contamination.