What is a single-stage centrifugal air compressor?

Centrifugal air compressors generate flow and pressure by utilizing centrifugal force. Centrifugal technology is a highly efficient method for producing compressed air.

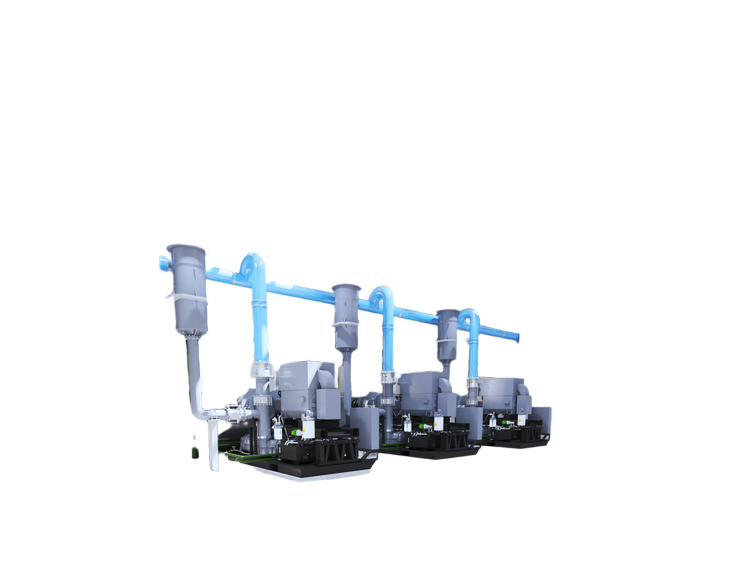

The gearbox equipped with a main drive shaft is driven by a motor. The gearbox and the main drive shaft jointly drive the high-speed shaft equipped with one or more impellers. A single-stage centrifugal compressor has only one impeller and can generate air with a pressure as high as 2 bar(g).

What are the differences between single-stage and two-stage compressors?

The term "stage" refers to the number of compression stages that air undergoes to achieve the required pressure. The high-speed rotating impeller forms dynamic pressure accumulation in the compressor. The number and stages of the impellers will depend on the required outlet pressure.

For applications requiring 2 bar(g) or less pressure, a single impeller or a single-stage compressor is sufficient to meet the pressure requirements. Higher pressure can be achieved by using two-stage or three-stage compressors.

Advantages

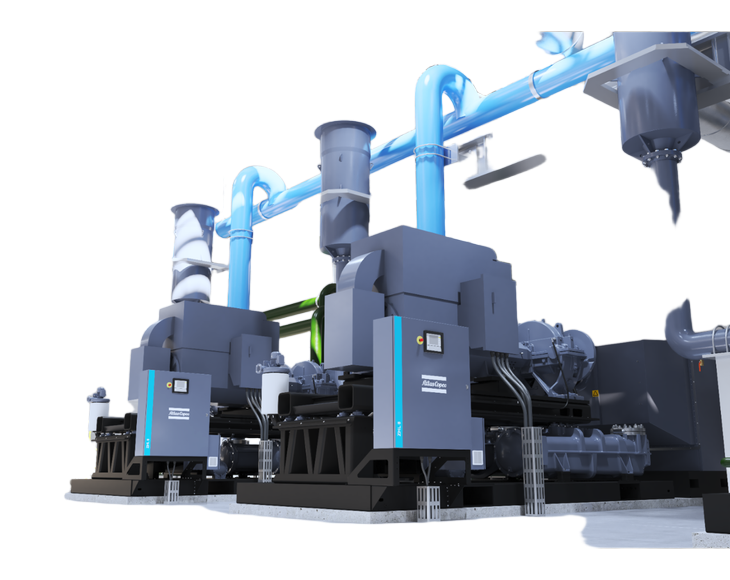

The centrifugal compressor adopts our proprietary backward-curved impeller design, which enables each model of different power and pressure to perform outstandingly. Different types of impellers enable you to select centrifugal compressors of appropriate specifications for a wide range of applications. With our wide range of impeller types, no matter how complex and changeable the working environment is, we can optimize the performance of the compressor according to your specific needs.

Our ZHL centrifugal compressors are driven by different high-efficiency motors. The low-voltage model (not exceeding 560kW) is equipped with a built-in star/delta starter. Offer different motor options, including air-cooled and water-cooled types.

Imported guide vanes can efficiently adjust the flow rate, thus easily responding to changing air demands. Compared with using imported valves, adjustable imported guide vanes can save up to 9% of energy. The imported guide vanes are controlled by actuators based on servo motors, which can economically and reliably control the flow rate throughout the entire regulation range of the compressor to meet different air requirements.

Our after-cooler combines compactness, low approach temperature and very small pressure drop, which can maximize overall energy efficiency as much as possible.