Oil-injected industrial air compressors ranging from 3.5 to 10.9 bar

What makes our GA stand out?

The concept is simple and the design is outstanding

Atlas Copco's GA series is specifically designed to achieve low energy consumption, high reliability and maintainability. All components are easy to maintain, and the parts that require the most frequent maintenance are centrally arranged together. The excellent entrance design enables access to all components when a large amount of maintenance work is required. This makes the maintenance time only half of that required by similar designs.

Comprehensive warranty covering all aspects

Atlas Copco offers customers a complete 5-year warranty enhancement plan for the entire machine. This ensures smooth operation in the harsh environments that GA must confront. The applicable industries include mining, metal smelters or cement plants, etc.

Advantages

High energy efficiency

The core component of the GA compressor is the advanced oil-injected screw rotor, which adopts SmartInjection technology and is equipped with an efficient oil-cooled IE4 grade or higher motor. The efficient transmission system, combined with powerful cooling capacity, low internal pressure drop and precise control of Elektronikon® Touch, ensures that the compressor operates with outstanding efficiency.

Ensure reliability under extremely harsh conditions

The drive system of the GA compressor has an IP66 protection rating, which is immune to environmental dust and moisture, ensuring reliable operation under harsh conditions and in an ambient temperature of up to 55°C/131°F

Reduce maintenance time

All maintenance components are centrally arranged together for easy inspection and repair, significantly reducing maintenance time. If a greater degree of maintenance is required, the excellent entrance design enables you to have access to all components. Each component is also designed in a form that is convenient for maintenance, and the required maintenance time is reduced by half compared to traditional designs.

Integrated compressor room

High energy efficiency

Compared with previous generations of VSD compressors, our hybrid GA screw compressor can save up to 8% of energy consumption.

Higher regulatory capacity

The combination of fixed-frequency and variable-frequency motors can achieve a regulation ratio as high as 85%, thereby providing greater operational flexibility without energy consumption.

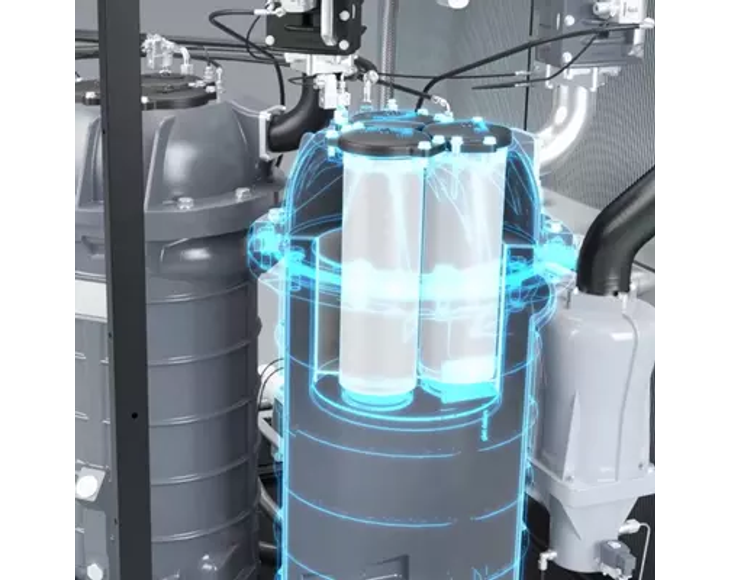

Single-host operation

Our hybrid compressor is equipped with two independent oil circuits, which means you can rely on a single motor to operate when needed or when there is a problem with one oil circuit. With a hybrid compressor, you don't have to worry about production halts.